Izakhono eziPhambili

- Ubuchule boBugcisa

Ukubumba Inaliti YamaCandelo Amaninzi

Itekhnoloji yokubumba inaliti yeHongrita enamacandelo amaninzi inikezela ngeenzuzo ezininzi ezibalulekileyo kwicandelo lokwenziwa kweplastiki:

Ukuphuculwa kwemveliso

Ukuhlanganiswa kwenkqubo

Ukuguquguquka koyilo

Ukuphucula amandla okubopha

Ixabiso lemveliso elincitshisiweyo lexesha elide

Ukunciphisa inkunkuma

Uhlobo olungcono lwezinto eziphathekayo

Ukusebenza kwemveliso kunye nokuphuculwa kokuqina kwayo

Iyanobuhlobo nokusingqongileyo kwaye iyasebenza kakuhle

Isikhunta se-Multi-Cavitation

Isikhunta sikaHongrita esinee-cavitation ezininzi senza ukubumba kweplastiki kube luncedo ngakumbi:

Ukuphuculwa kokusebenza kakuhle kwemveliso

Ixabiso lemveliso elincitshisiweyo lexesha elide

Umgangatho wecandelo ohambelanayo

Ixesha lokutshintsha ngokukhawuleza

Ubungakanani bokubumba obuncitshisiweyo

Ukulungiswa kwezixhobo

Ukuseta imveliso okulula

Ukuhlangabezana neemfuno ezinkulu

Ukubumba i-LSR/LIM Injection

Itekhnoloji yokubumba i-LSR ye-Hongrita inika iingenelo ezininzi ezenza ukuba ibe lukhetho olukhethwayo kwiindlela ezahlukeneyo zokusebenza:

Ukuchaneka okuphezulu

Ukunciphisa i-flash kunye nenkunkuma

Izakhono ezininzi kunye nokudibanisa ngaphezulu

Amaxesha omjikelo amafutshane

Umgangatho ohlala uhleli

Isisombululo sokuTshintshwa kweNjovo echanekileyo kunye neSisombululo seTurnkey

- - Inkqubo yokubumba

- - Isisombululo seTurnkey

- Itekhnoloji yokubumba i-plastiki ye-Hongrita inika uluhlu olubanzi lweenzuzo, ezinegalelo ekukhuphisaneni nasekuphumeleleni kwayo kwishishini lokuvelisa iplastiki:

- Izicelo ezininzi

- Izakhono ezininzi

- Ukwenziwa kwezinto ngobuchule

- Ukuchaneka okuphezulu kunye nobunzima

- Ukusebenza kakuhle kweendleko

- Iinkonzo ezidibeneyo

- Umgangatho ophezulu

- Uzinzo

Ukulinganisa imveliso ngokwedijithali kunye nobugcisa

Iworkshop ye-ISBM

B200II

MV2400S

Ifomu 3000HP

Izixhobo eziBalaseleyo

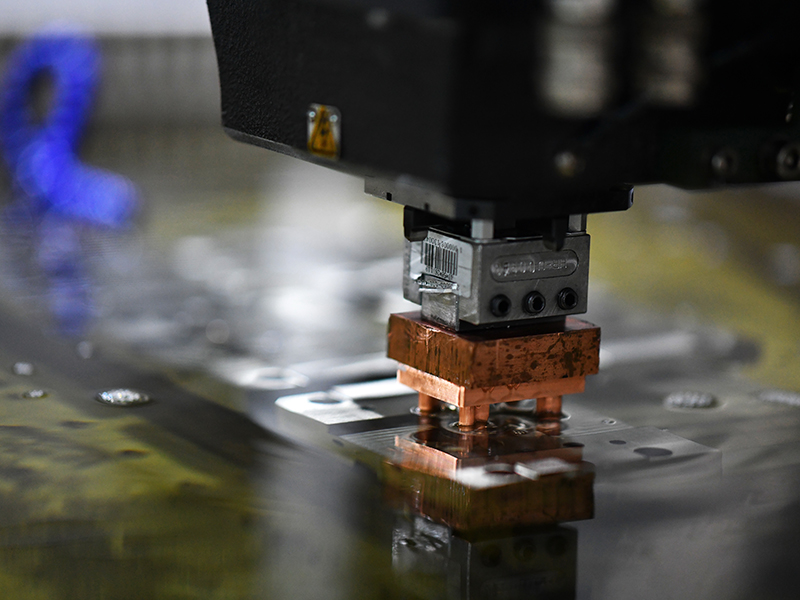

I-EDM

I-CNC

Ukusila kwe-CNC Turning

Indawo Yokusebenzela Yokufaka Inaliti

Indawo yokusebenzela yezonyango

Ukuqukumbela, iteknoloji yokubumba iplastiki yaseHongrita inika iingenelo eziphambili kwizicelo ezahlukeneyo, ubuchule obunamacandelo amaninzi, ukwenziwa kwezinto ngobuchule, ukuchaneka okuphezulu kunye nobunzima, ukusebenza kakuhle kweendleko, iinkonzo ezidibeneyo, ulawulo lomgangatho, kunye nokuzinza. Ezi nzuzo zibeka iHongrita njengenkokeli kushishino, ekwaziyo ukubonelela ngezisombululo zeplastiki ezintsha nezisemgangathweni ophezulu kumacandelo ahlukeneyo ngelixa isamkela imveliso eluhlaza.